How To Set Up Mechanical Disc Brakes

A rubbing or underperforming disc brake tin often make a ride frustrating. Regardless of make and model, this article will help you gain the knowledge yous need to suit mechanical disc brakes.

1

Preliminary Info

What Tools do I need?

- Appropriate wrench for pad adjuster, compression commodities and mounting bolts. This may include T25 Torx®-compatible, or 3, 4, or 5mm hex: Hex & Torx®-Uniform Tools

- Torque wrench or torque commuter with advisable bits: Torque Tools and Bits

- Cablevision cutter: CN-ten

- Flashlight & low-cal piece of paper

Mechanical brake systems utilise a cablevision to actuate a lever arm on the caliper that engages the pads. Hydraulic systems use fluid through a hose to engage the pads. Here are the central components of the mechanical disc braking arrangement:

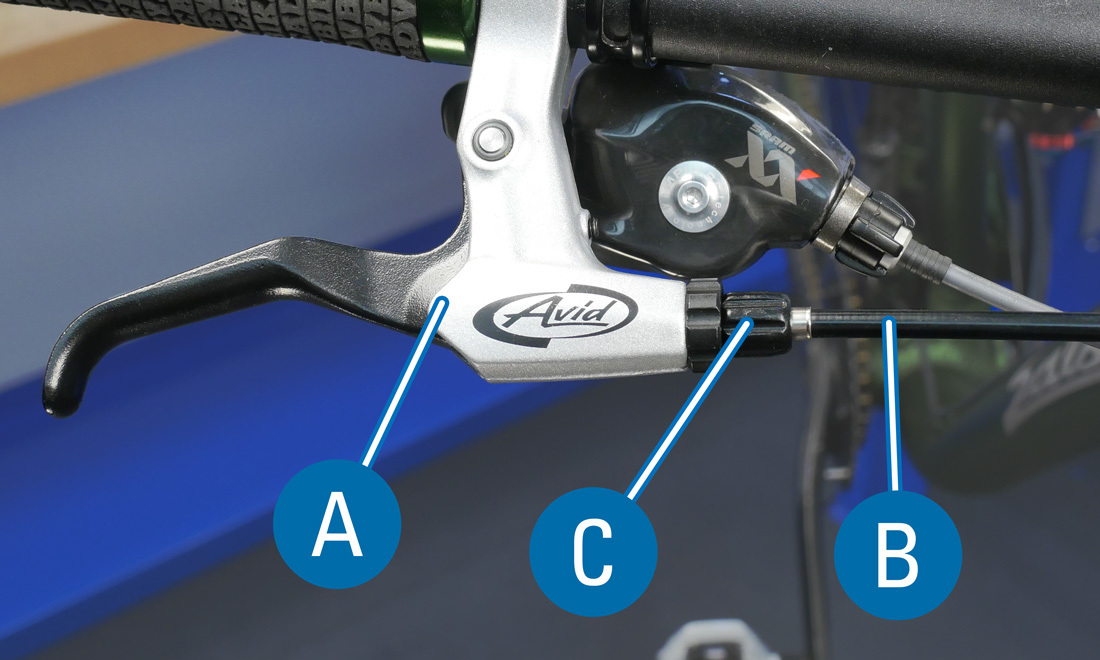

- BRAKE LEVER: The brake is actuated past a brake lever at the handlebars.

- CABLE & HOUSING: On a mechanical organization, the brake lever pulls a cablevision, which runs through housing down to the brake caliper.

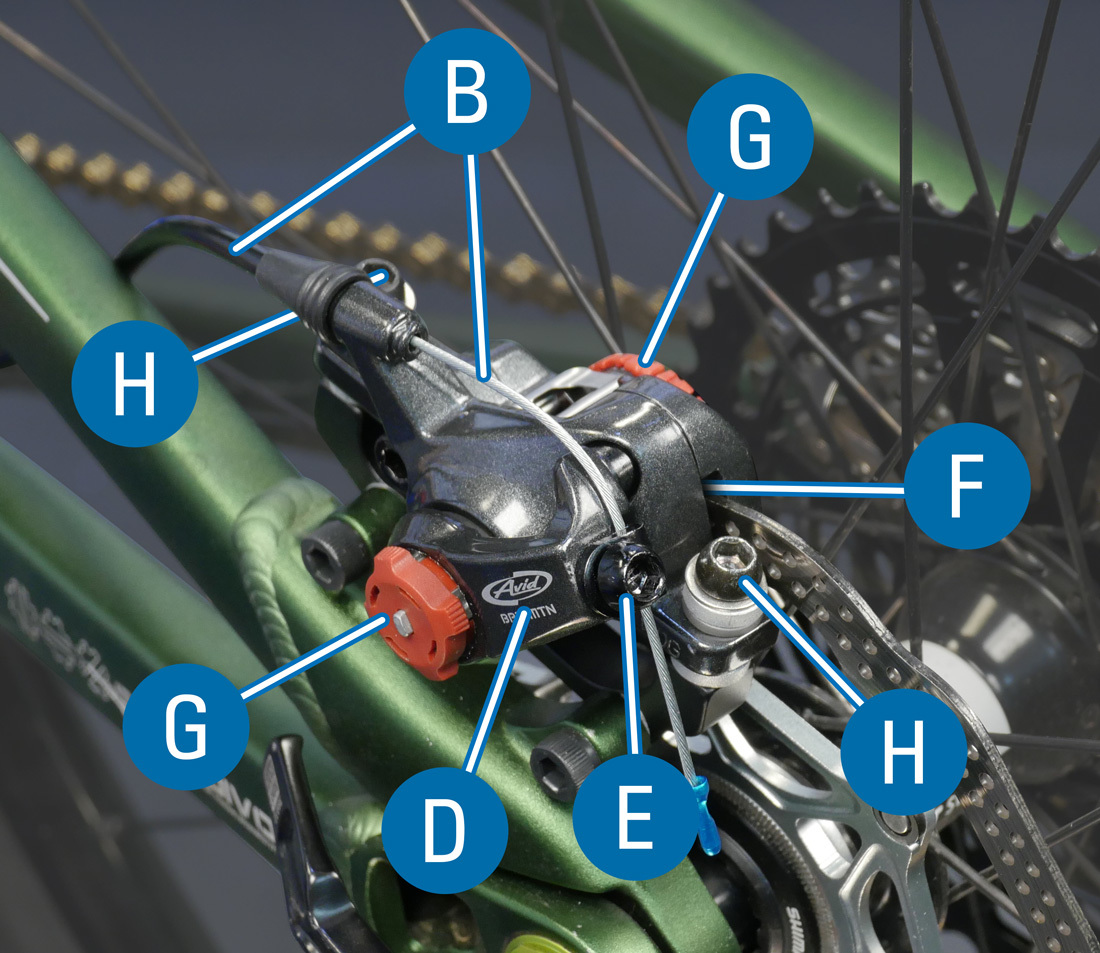

- BARREL ADJUSTER: The housing tin can finer be lengthened or shortened with the twist of a butt adjuster, which may be constitute at the lever and/or the caliper.

- LEVER ARM: The brake cablevision actuates a lever arm. Most mechanical caliper designs have 1 lever arm that moves only the outer brake pad when actuated. The rotor then flexes over into contact with the inner near pad. There are as well designs that have ii lever arms. On these calipers both pads motion evenly into the rotor.

- PINCH Commodities: The cable is secured to the lever arm using the compression bolt.

- PADS: The lever arm squeezes the brake pads to the rotor, causing friction to slow or stop the bike. Restriction pads consist of braking chemical compound bonded to a bankroll plate.

- ADJUSTERS: Calipers are equipped with pad adjusters that move the brake pads in or out from the rotor. Some calipers have only one adjuster that moves the inner pad, while other calipers have both an inner and outer pad adjuster.

- MOUNTING BOLTS : Caliper disc brakes secure to the frame or fork using two mounting bolts. The location of these bolts tin can vary depending on the frame mount standard: Post Mount, IS Mount, or Apartment Mount.

- MOUNTING HOLES: Disc brake systems are equipped with wide holes that allow for lateral motility relative to the rotor. These can be found on the caliper body (postal service mount), the frame (rear flat mount), or the caliper adapter (front flat mountain).

2

Alignment Procedure

Before beginning the caliper alignment procedure, it is important to check other components that could consequence your brake adjustment are set up correctly.

- Ensure that the bike is fully seated in the drop outs. This, in plough, ensures that the rotor is properly positioned in the caliper.

- Drag the bike, spin the wheel and inspect the rotor in the caliper. If the rotor shows a lot of lateral movement, information technology tin be difficult or incommunicable to suit the pads to non rub. The rotor volition need to be trued or replaced.

- Turn the barrel adjusters all the way in (clockwise) at the lever and at the caliper if applicable.

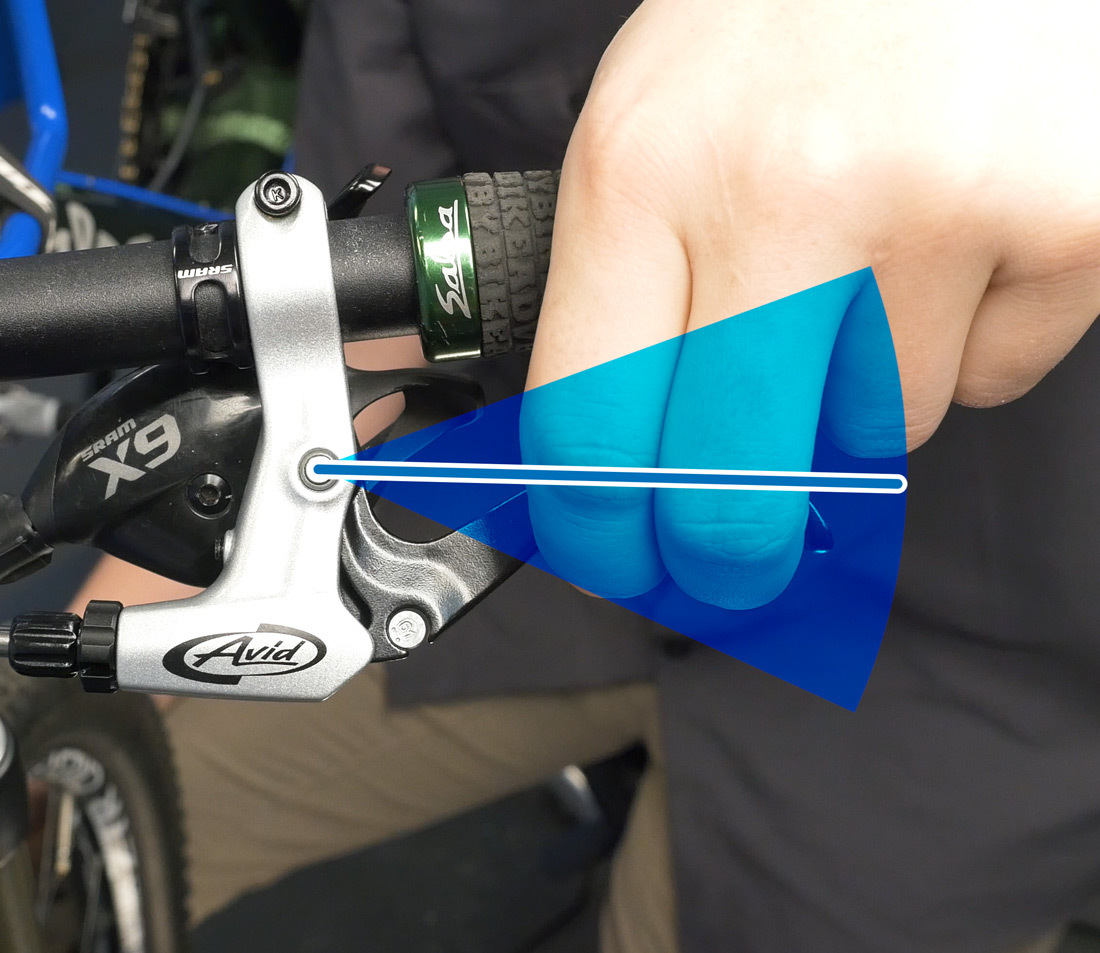

- Check that the lever arm is released and in its relaxed position by loosening the cable pinch bolt. This ensures full lever arm travel during braking.

- Pull the cable tight so it is gratuitous of slack and tighten the cable compression bolt.

- Exist careful non to motility the lever arm when tightening the pinch bolt. This is important because the lever arm only has a small amount of useful motion.

3

Blueprint-Specific Instructions

The alignment process varies depending on the caliper design.

Unmarried Lever Arm — Inner & Outer Pad Adjusters

The cable pulls a single arm, which moves the outer pad

The outer and inner pads characteristic an adjuster

- Begin by loosening the caliper mounting bolts. This alows the caliper to float.

- Plough the outer pad adjuster all the way out (counterclockwise), then back in 1 full revolution. This leaves room for future adjustment.

- Turn the inner pad adjuster clockwise until the pads lock confronting the rotor.

- Snug the caliper mounting bolts to align the caliper torso over the rotor. Full tightening will occur later good pad alignment is confirmed.

- Loosen both the inner and outer pad adjusters evenly, 1/4 to 1/two turn

Unmarried Lever Arm — Inner Pad Adjuster Only

The cable pulls a single arm, which moves the outer pad

Simply the inner pad features an adjuster

- Begin by loosening the caliper mounting bolts. This alows the caliper to float.

- Turn the inner pad adjuster all the way in (clockwise), then dorsum off virtually 1/four turn

- Pull and hold the brake lever tight. This aligns the caliper torso to the rotor.

- Snug the caliper mounting bolts.

- Release the brake lever.

- Back off the pad adjuster another 1/4 turn.

Dual Lever Arm

- Begin by loosening the caliper mounting bolts. This allows the caliper to bladder.

- Turn the inner and outer pad adjusters all the way out (counterclockwise).

- Pull and concur the restriction lever.

- If the lever goes all the mode to the handlebar without the brakes making contact, release the lever and tighten both pad adjustment screws 1/2 turn. Repeat tightening evenly until pad contact is felt at the lever.

- Snug the caliper mounting bolts to hold the alignment of the caliper body over the rotor. Full tightening will occur later on good pad alignment is confirmed.

- Release the lever.

4

Final Adjustments

These concluding adjustments apply to all mechanical disc brakes. The cease goal is a caliper that is parallel to the rotor, with even gaps on each side and an adequate lever feel. Even though setting the pads against the rotor should theoretically take aligned the caliper correctly, it is common for further adjustments to exist required.

Lever Position

- Pull and release the brake lever a few times to check the clearance at the grip. Check that the lever travel feels adequate to tiresome and stop the bicycle. Typically, the pads should feel like they are contacting the rotor at a minimum of one-half the lever travel.

- Make adjustments equally necessary using the pad adjusters, moving the pads in and out evenly on both sides.

Pad Rub

- Spin the wheel and bank check for pad rub.

- If there is no pad rub, the alignment is complete — skip to FINAL STEPS.

- If the wheel slows quickly, or makes a rubbing racket, the pads need further adjustment.

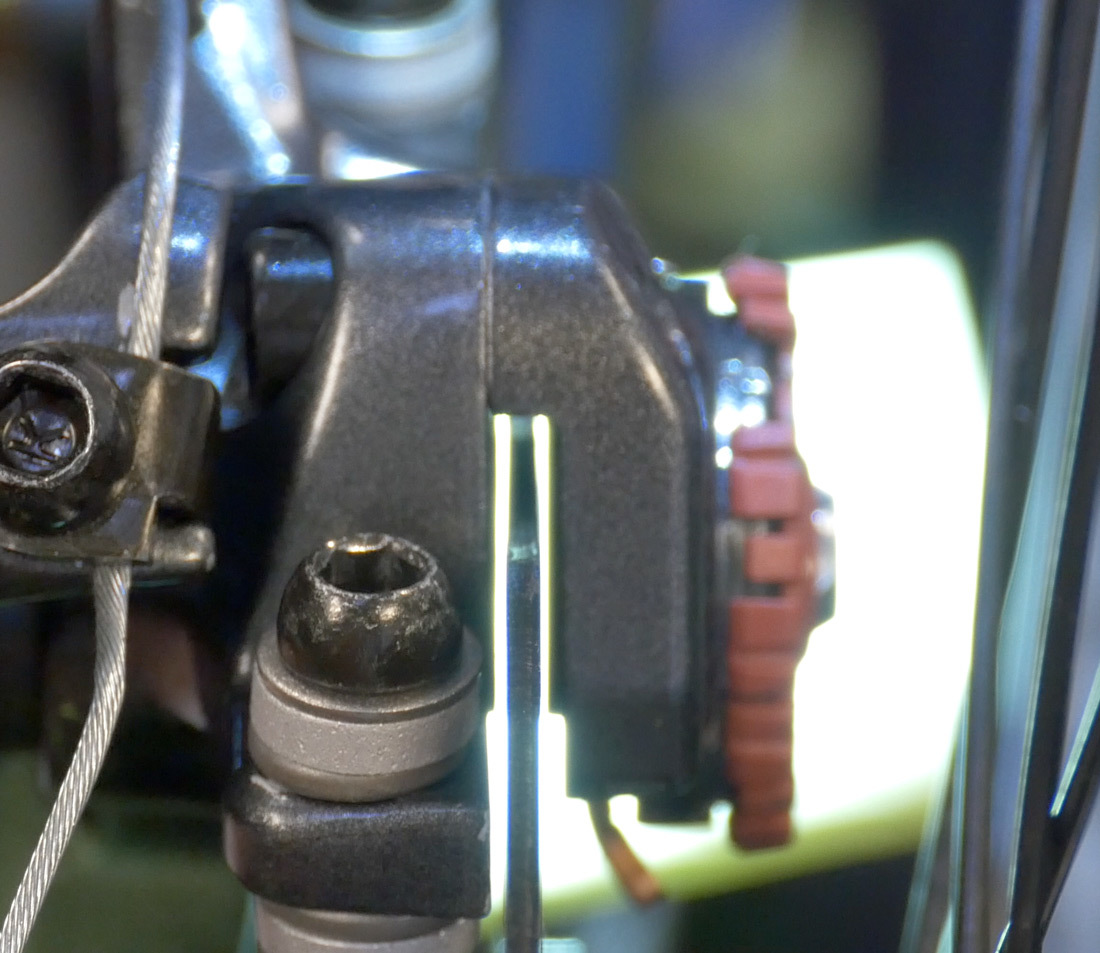

- Inspect the alignment of the pads to the rotor. You may need to reorient the bike for a better view.

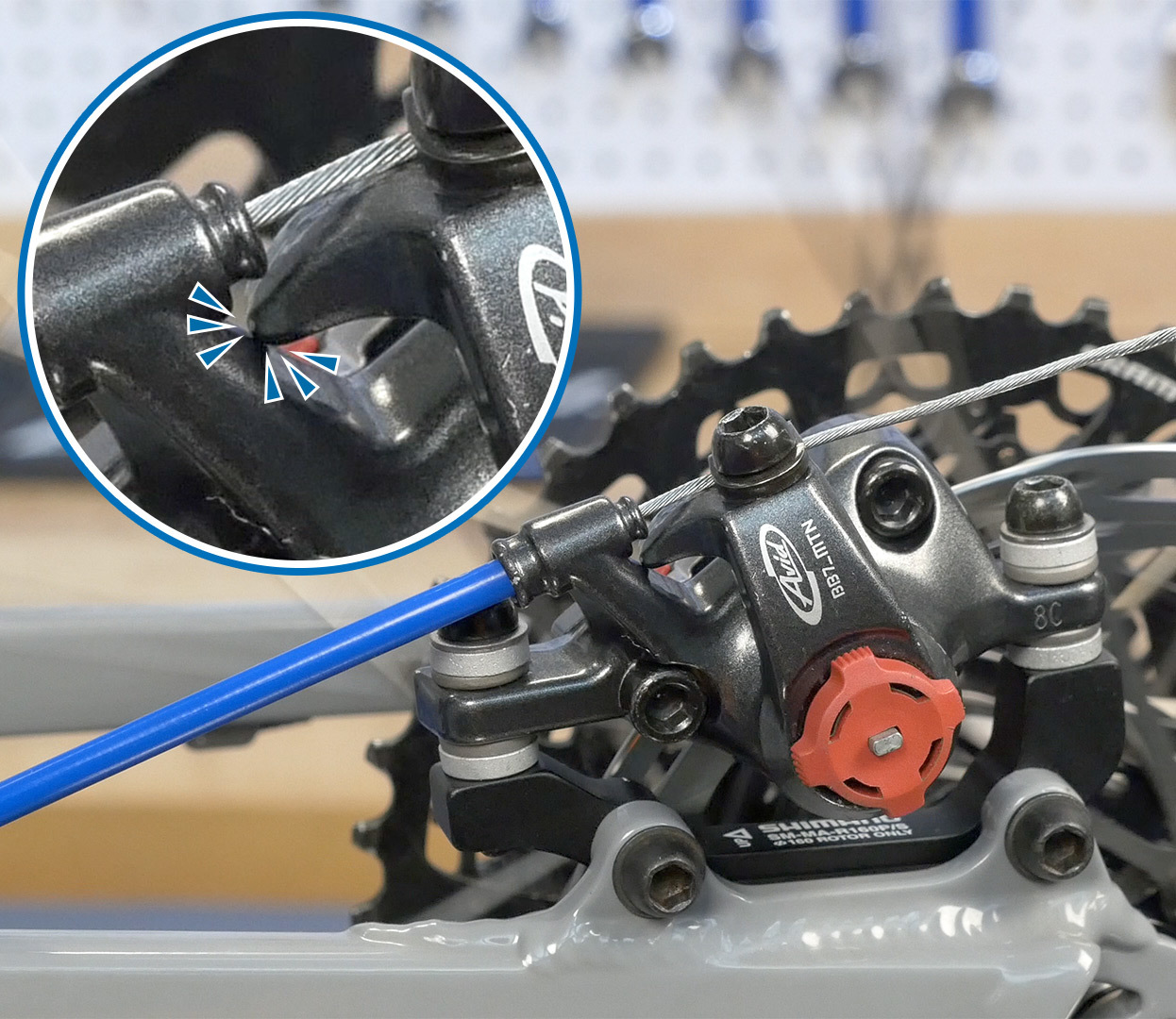

- Information technology is helpful to backlight the caliper body by shining a lite on a piece of white paper or cloth. This makes the pad clearances easier to see.

A small flashlight pointed at a sticky annotation held backside the caliper...

...makes the alignment of the pads to the rotor much more visible

- If the pads are non parallel to the rotor, the caliper body needs to be adapted. Loosen one commodities, move the body slightly to the side that has no gap, snug the bolt and re-check the alignment.

- Keep in mind that making one aligning may affect others.

- If pads appear parallel, but there is still rubbing, loosen the pad adjuster on the side with pad rub in 1/4-plough increments until it is gone.

- Re-check the clearance at the lever and adjust as necessary.

For calipers with inner pad adjustments merely, the procedure for adjusting outer pad clearance is unlike:

- Loosen 1 of the mounting bolts, move the caliper a pocket-size corporeality toward the side that is rubbing, and re-snug the bolt.

- Repeat these steps until the rubbing is eliminated.

Concluding Steps

- Finish past fully tightening the compression bolt and each mounting bolt. Typical torque specs are about 6 Nm for the mounting bolts and four Nm for the pinch bolt.

- If yous have installed a new brake cablevision, or if the cable has excessive slack, cut the cable roughly 1 inch past the pinch bolt and add an end cap to prevent fraying.

v

Other Considerations

The brake is at present properly adjusted and ready to exam ride. Here are some other considerations that may come into play during this process:

Brake Pad Wear

As the pads wear, you will need to make farther adjustments to keep the lever feel consistent. Tighten the pad adjusters to bring the pads closer to the rotor. Motion the adjusters evenly in small increments and exam at the lever.

Calipers with a single pad adjuster will need to reset the caliper position from scratch equally the pads wear. Refer back to section #2.

Important: Practice not use the butt adjuster to move the pads inward as they article of clothing. This will eventually motility the lever arm to a position where it is contacting another part of the caliper, preventing the pads from contacting the rotor.The barrel adjusters should only exist used to take out cablevision slack as the cablevision and housing system settle in.

Cable & Housing Wear

Worn, dirty or corroded cable and housing tin can drastically affect the operation of the braking organisation. Replace these components if necessary — see Restriction Housing & Cable Installation for Upright Bars or Drib Confined.

Mount Facing

In some cases, frame mounts may not exist perfectly square to the rotor, causing lateral misalignment at the caliper. In that location is often no adjustment possible for this type of misalignment, simply a professional person shop may be able to face or automobile the mounts with the Park Tool DT-v.2 to ameliorate alignment.

Conical Washers

Some manufacturers use a system of mating conical washers. These help to marshal the vertical face of the pads to the rotors. These washers must be designed into the system, and cannot be added to brakes non designed for them. Additionally, if the brakes came with these washers they must be used. If there are conical washers just on meridian of the caliper, they should remain on tiptop.

Source: https://www.parktool.com/en-us/blog/repair-help/mechanical-disc-brake-alignment

0 Response to "How To Set Up Mechanical Disc Brakes"

Post a Comment